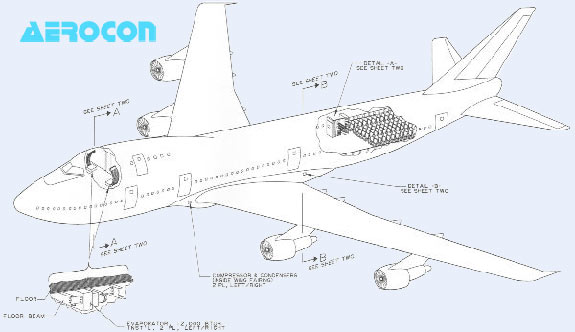

Air Conditioning

Aerocon can design custom air conditioning (environmental control) systems for a variety of aircraft. Typical requirements are humidification, de-humidification, filtering, noise reduction, and thermal control. Our on-staff Air Conditioning DER ensures that designs can be implemented and certified rapidly. Many systems are currently in use, worldwide.

Aerocon designs vapor cycling air conditioning systems for a wide range of applications:

- Cockpit and executive quarters

- Electronic warfare suites / Special mission equipment

- Avionics racks / bays

- Operator stations

- Medevac / Hospital aircraft

The system operates from the auxiliary power unit (APU) or main engine generator, and requires no ground equipment. It is effective even on hot and humid days. Aerocon's superior design is quiet, lightweight, small, and extremely reliable. Components are built to military specifications, and parts support is guaranteed.

Typical VCAC System

The operational performance of the vapor cycle system may be varied as a function of the volume of cooling air required and other aircraft electrical requirements. The system can be operated from an auxiliary power unit (APU), ground power unit (GPU), or the main engine electrical generating system.

Each 24,000 BTU of cooling requires 5 KVA of continuous electrical power (surge requirement of 7 KVA). The basic characteristics of a 2 ton VCAC system are shown below:

| Component |

|

Height | Width | Depth | Weight |

|

| Compressor Motor |

|

9.0" | 14.0" | 13.4" | 39 lbs. |

|

| Condenser Blower |

|

14.6" | 16.5" | 11.1" | 19. lbs. |

|

| Evaporator |

|

10.4" | 12.4" | 11.75" | 11.0 lbs. |

|

| Receiver Dryer |

|

4.22" | 3.8" | 8.0" | 1.8 lbs. |

|

System Characteristics

The following table shows characteristics for the above configuration.

| Electrical System | 115 / 208v 3-phase AC |

| Airflow | 800-1000 Cubic feet/minute (CFM) |

| BTUH | 24,000 |

| Flight Rated | In-flight operable to 40,000 feet |

| Cooling performance | 30ºf Temperature drop between inlet and distribution duct outlet. |

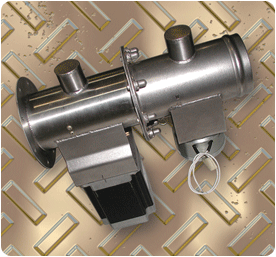

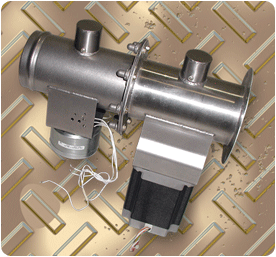

Air-Flow Control and Shut-Off Valve

AEROCON’S Air-Flow Control and Shut-Off Valve is installed on modified aircraft to provide supplemental avionics cooling.

- Meets and exceeds applicable FAA and EASA regulations.

- Electronically controlled, electric motor actuated butterfly type valve.

- Controls include operation for full open, full closed, and automatic constant mass flow.

- Provides a constant 18 + / - 2 lb. /

min airflow during ground and flight conditions.

• 3” in diameter or greater – per customer specs

• Easily mounted on the aircraft

• Flow control value will fail in closed position

Note: airflow exiting the valve is discharged into an unpressurized compartment or ducted to avionics located in the unpressurized compartment.